After just 10,000 km, a vehicle loses efficiency and can therefore no longer provide the performance intended by the manufacturer.

Operational deposits in the entire fuel and oil system are usually not recognized when driving a vehicle regularly. Thus, after the first few kilometers, a gradual process starts that influences the full performance of the engine. Vehicle drivers usually do not notice the consequences at all or only when it is too late and a cost-intensive visit to the workshop is necessary.

Why are the systems polluting?

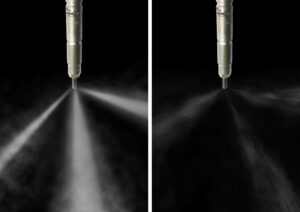

To protect the environment, vehicle manufacturers are increasingly turning to smaller and more efficient engines. But various exhaust aftertreatment systems, both for diesel and petrol engines, are now standard for every newer vehicle. Thus, due to the higher injection pressures, the design of injectors and injection nozzles is becoming more and more delicate and therefore more susceptible to dirt and coking. Conversely, this also means that the spray pattern deteriorates over time and optimal combustion is no longer guaranteed.

Left: injection nozzle with optimal spray pattern and therefore optimal combustion Right: poor spray pattern due to clogged spray needle

Aftertreatment systems (DPF, OPF, catalytic converter, EGR, etc.) used to reduce emissions can become clogged and prevent ideal flow. As soon as just one of these components impairs the optimum exhaust gas or fuel flow, the full performance of the engine can no longer be guaranteed.

The solution can be so simple!

We have made it our task to tackle these problems and will present you with effective and user-friendly solutions for your vehicle over the next few weeks.

#SAVE FUEL

Highest fuel efficiency by removing carbon deposits.

#INCREASE PERFORMANCE

Maximum power through efficient engine operation.

#REDUCE COSTS

Extreme cost savings through cleaning instead of replacement.

#PROTECT THE ENVIRONMENT

Lowest possible emissions thanks to optimal combustion.